The sewage suction and purification vehicle is a brand new model designed by Jining Xiangrui Engineering Machinery Co., Ltd. The equipment mainly goes through three procedures: sewage residue separation, flocculation reaction, and solid-liquid dehydration. First, the machine is used to separate the sewage residue, separating solid wastes such as stones, paper towels, plastic bags and other impurities, and producing solid wastes larger than 15mm, which can be treated as domestic wastes; After the separation of solid slag, the next step of treatment is carried out. The wastewater flocculation reaction system is used to combine the fecal water and the wastewater flocculation reaction; Then, the sewage combined with the reaction will enter the final screw folding machine dehydration system to become the raw material of organic biological fertilizer, and the separated water will meet the sewage discharge standard, which can convert the septic tank sewage into reusable resources, truly realizing energy conservation, environmental protection and harmless, while creating economic benefits and improving the added value of environmental protection. This new model is a semi-automatic high-tech product that is specialized in treating septic tanks, kitchen sewage pools, settling tanks of municipal sewage treatment plants, etc. It is a new product designed with new technologies and new processes to quickly and innocuously treat all sewage; The sewage absorption and purification vehicle is composed of vehicle chassis, sandwich power take-off, generator, electric control system, sewage separation system, dosing system, screw stacking dehydration system, high-pressure cleaning system, etc; Its reasonable and reliable design ensures the speed of sewage treatment and reduces the cost of sewage treatment. The technical performance of the whole vehicle is ahead of that of similar products.

Parameter

| No | Name | Specifications | Quantity |

| 1 | Vehicle name | Sewage treatment truck | 1 |

| 2 | Overall dimensions of the whole vehicle | 7300X2300X3300 | |

| 3 | Total mass | 10275kg | 1 |

| 4 | Unladen mass | 10080kg | |

| 5 | Chassis models | BJ1128VGJEA-FK | 1 |

| Engine | F3.8NS6B156 (Cummins 115kw 156hp) | ||

| 6 | Weichai Power diesel generator set | CY4SK261 (Chaochai 125kw 170hp) | 1 |

| 7 | 4 cylinders 30 kW | PC | |

| 8 | Dimension | 1400×750×910mm | |

| Water ring vacuum pump cooling box | 7.5Kilowatt (stainless steel)) | ||

| ozone generator | JP-E50(stainless steel shell) | ||

| 9 | Oil free air compressor | 0.7MPa,1.1Kilowatt (iron) | 1 |

| 10 | Pneumatic valve | (stainless steel) | 1 |

| 11 | Double plate dehydrator | XR-HXH-716D 0.75Kw) Auspicious homemade) | 1 |

| 12 | Medicine box | Auspicious homemade (stainless steel) | 1 |

| 13 | Coagulation mixing tank | Auspicious homemade (stainless steel) | 1 |

| 14 | Inner drum solid waste separator | Auspicious homemade (stainless steel) | 1 |

| 15 | Tank | 4 cubic meters (stainless steel) | 1 |

Brief Introduction Of Equipment

The sewage suction and purification vehicle is a brand new model designed by Jining Xiangrui Engineering Machinery Co., Ltd. The equipment mainly goes through three procedures: sewage residue separation, flocculation reaction, and solid-liquid dehydration. First, the machine is used to separate the sewage residue, separating solid wastes such as stones, paper towels, plastic bags and other impurities, and producing solid wastes larger than 15mm, which can be treated as domestic wastes; After the separation of solid slag, the next step of treatment is carried out. The wastewater flocculation reaction system is used to combine the fecal water and the wastewater flocculation reaction; Then, the sewage combined with the reaction will enter the final screw folding machine dehydration system to become the raw material of organic biological fertilizer, and the separated water will meet the sewage discharge standard, which can convert the septic tank sewage into reusable resources, truly realizing energy conservation, environmental protection and harmless, while creating economic benefits and improving the added value of environmental protection. This new model is a semi-automatic high-tech product that is specialized in treating septic tanks, kitchen sewage pools, settling tanks of municipal sewage treatment plants, etc. It is a new product designed with new technologies and new processes to quickly and innocuously treat all sewage; The sewage absorption and purification vehicle is composed of vehicle chassis, sandwich power take-off, generator, electric control system, sewage separation system, dosing system, screw stacking dehydration system, high-pressure cleaning system, etc; Its reasonable and reliable design ensures the speed of sewage treatment and reduces the cost of sewage treatment. The technical performance of the whole vehicle is ahead of that of similar products.

Schematic Diagram Of Equipment Working Principle

The vehicle sucks the dirt of all sewage pools into the solid-liquid separator through the water ring vacuum pump, and separates the solid wastes such as stones, paper towels, plastic bags, hair and other impurities through the drying separation drum in the separation box; After solid-liquid separation, further treatment shall be carried out. After automatic dosing according to the concentration of fecal water through the liquid medicine analysis system, the fecal water shall be mixed with the liquid medicine, and the sewage generated by the fecal water and liquid medicine shall be sent to the final dehydration system to become the raw material for the production of organic biological fertilizer. The water from the double deck plate dehydration and our love has reached the secondary reclaimed water discharge standard, and the septic tank sewage has been converted into useful and reusable resources, which truly realizes energy conservation, environmental protection and harmless treatment, and creates recyclable and sustainable economic benefits.

Equipment Performance Characteristics And Advantages

- Intelligent operating system configuration: one button operation, fully automatic operation, remote control, intelligent full-automatic, computer automatic dosing, intelligent detection, automatic control and processing, one button full-automatic; At the same time, manual control of air and energy is also taken into account, which is beneficial to the physical and mental health of operators and improves the user experience. It can help the boss save 70000 to 100000 yuan/(one worker’s annual salary)

- Energy saving: The car uses Weichai four cylinder 30kW diesel autonomous generator, which has low fault, low noise, one piece control, self detection and self-help troubleshooting. At the same time, it can also be connected to 380V external power supply for operation, which has low energy consumption, low operating cost, low labor consumption, high work efficiency and high degree of operation safety. More than 80% of the processing work is automatically completed by equipment and machinery, and the amount of manual work is very small. Workers only need to operate buttons on the intelligent control platform to deal with it once, reducing the processing cost.

- Environmental protection: rapid deodorization and sterilization, no discharge of three wastes during the treatment process, low noise of equipment operation, and prevention of secondary pollution. Low energy consumption, energy conservation and environmental protection, odorless sludge after treatment can be sold as organic fertilizer to reduce treatment costs, and the separated water can be directly discharged or used.

- High efficiency: on-site processing, reducing processing links; It has a large processing capacity and can be operated continuously. It can process 15-30 cubic meters of septic tank sewage per hour and extract 100-1000Kg organic fertilizer. The moisture content of dewatered sludge is 70-80%, which can be quickly filtered and dried; It is especially suitable for first-line cities with high emission requirements; At the same time, for small and medium-sized cities that do not have strict discharge requirements, they can only be directly pumped and discharged after preliminary filtration, and can handle 80-150 cubic meters of sewage per hour. The treated sewage will not block the municipal pipe network, and meet the basic sewage discharge standard.

- With various functions, it can also realize the functions of flood control and drainage, mobile emergency power supply and lighting. It can play an important role in urban bridge, culvert drainage and emergency rescue in the rainy season, and has good social benefits. The car is beautiful and atmospheric in appearance design. The side door adopts wingspan opening mode, which does not occupy space after opening, and can block the wind, rain and sun. It is convenient for maintenance, beautiful and practical.

- This vehicle is different from other sewage suction vehicles or manure suction vehicles in that it has tank capacity limitations. The sewage purification vehicle can operate continuously and the septic tank can be operated at one time without needing to transport back and forth, saving customers a lot of time and cost. At the same time, different types of sewage suction and purification equipment can be installed according to customer needs to increase the treatment capacity.

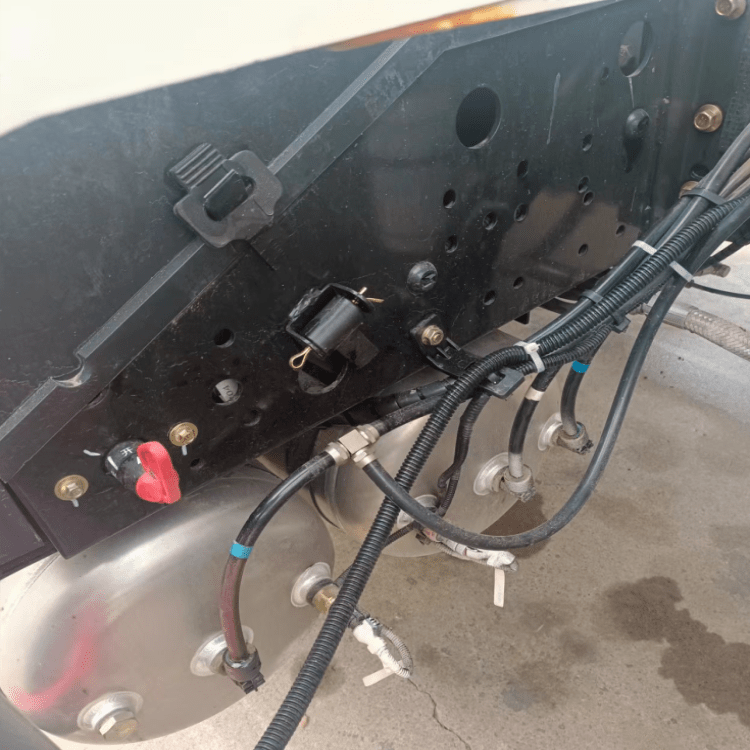

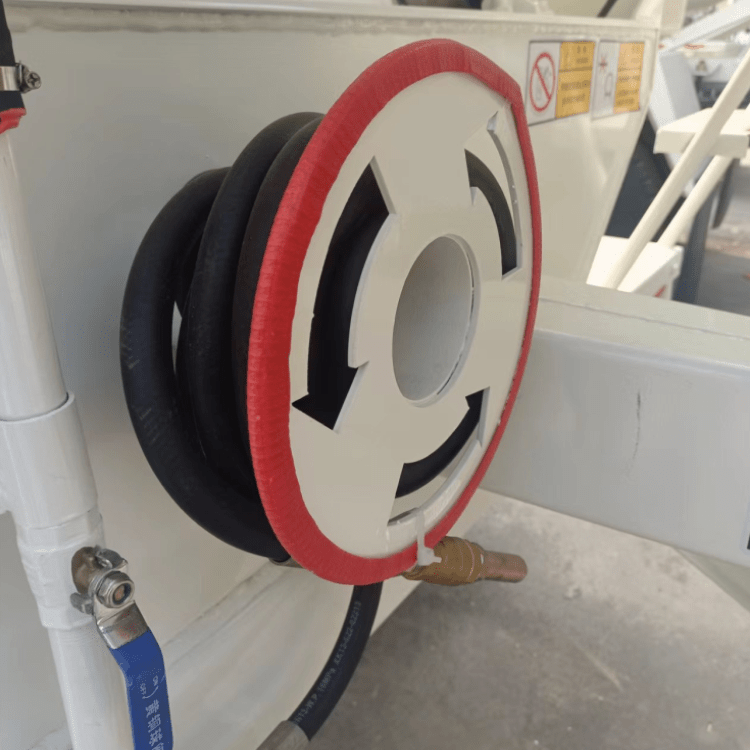

- The vehicle is equipped with high-pressure cleaning function, which can be used for professional pipeline cleaning and dredging. One vehicle can be used for multiple purposes, saving customers’ purchase costs; The main parts of the sewage treatment and purification vehicle are made of stainless steel, which not only has a long service life, but also is convenient for cleaning.

- The spare parts of the whole vehicle are purchased from domestic famous brands. After many tests, they have good performance, stable operation and durability.

Reviews

There are no reviews yet.